Here at KVA we achieve our goals through continuous planning, implementation, measurement, and improvements to the quality measurement system.

Engineering

The process that our engineering department uses when designing induction heating coils looks like this:

- We first are given a print for a workpiece with a desired pattern that the part needs to be heated and hardened to. With these specifications given to us by the customer, we are able to develop a coil that is needed to sufficiently treat the part.

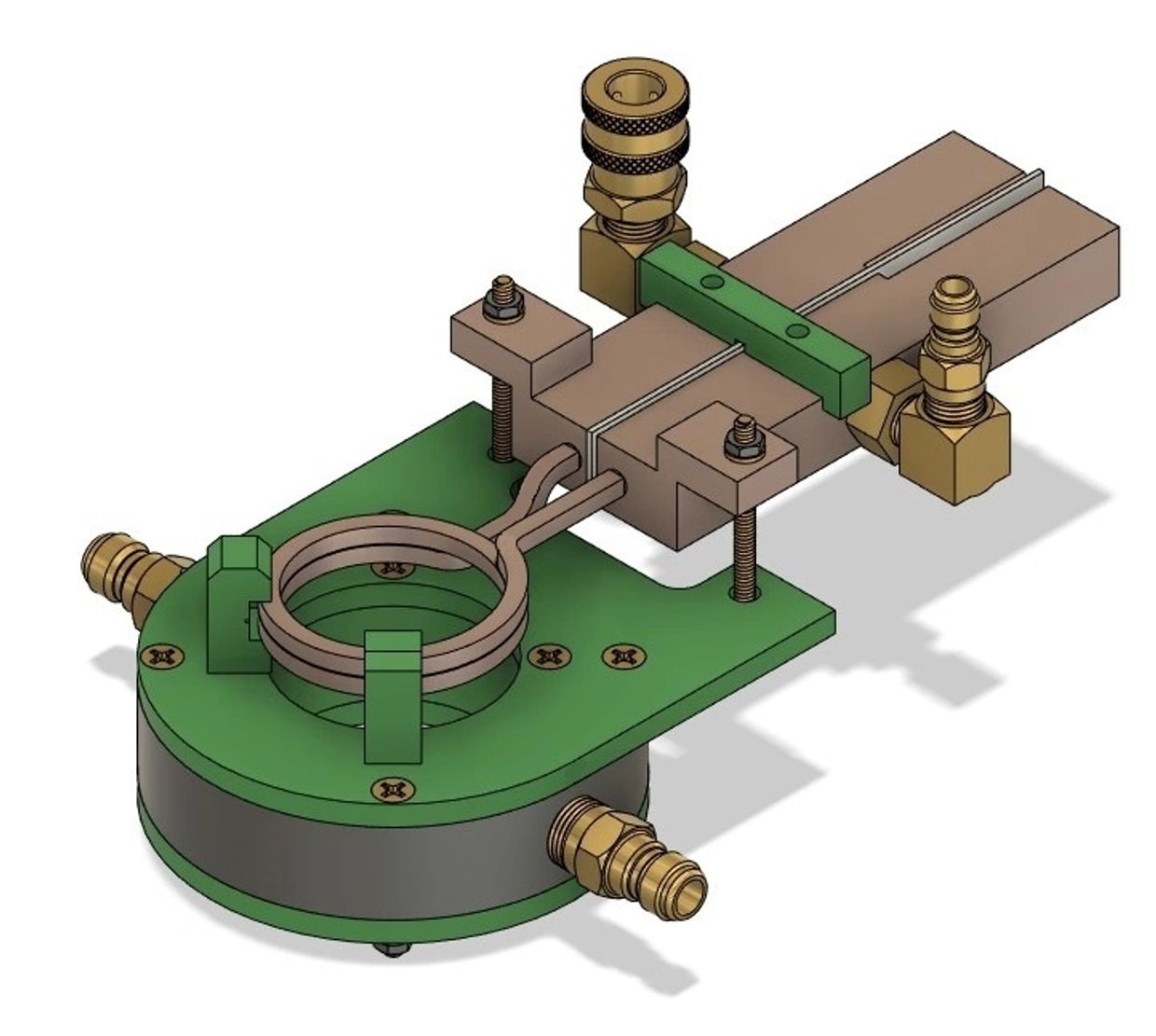

- Once the coil has been designed in AutoCAD 2D and it has been approved, we can then start on building the coil in Fusion 360. Fusion 360 is a 3D program we use to double check that the coils will work and there are no interferences. When our coil has been double checked and we see that there are no complications then it can be released for building.

- When prints have been sent out to the shop floor for building, our machinists are given the detail drawings in 2D and the assembly drawing in 2D as well as 3D. This way the machinist can see what parts they need to build on a detailed 2D drawing as well as how those parts assemble together on a separate 3D drawing.

Using both 2D and 3D design software has many different advantages. For one, it reduces any confusion that the machinist might have when they are constructing the coil. Having a 3D assembly drawing included with the 2D set of prints allows for the machinist to get a more clear idea of how the coil should be assembled, as well as notice any interferences that could be harder to recognize with a 2D drawing.

KVA INDUCTION CO. INC. AN INTERPOWER INDUCTION CO

34112 Doreka Dr, Fraser, MI, 48026, US

Copyright © 2021 KVA INDUCTION CO. INC. AN INTERPOWER INDUCTION COMPANY